Safety-Strip®: Quick & Safer Cable Removal

Traditionally, the outer jacket of downhole cables and control lines were removed using open blades, air-driven wire abrasive wheels or mechanical devices. This presented considerable risk of damage to the underlying cables and often resulted in operators suffering injuries to their hands, legs or abdomen.

Scratched or damage tubing surfaces can potentially prevent a good seal between the cable or tube and its termination. If this occurs during deck pressure testing, it will lead to rig downtime and if the poor seal leads to a subsequent failure during operation it will require removal and re-installation.

Solutions Expertise

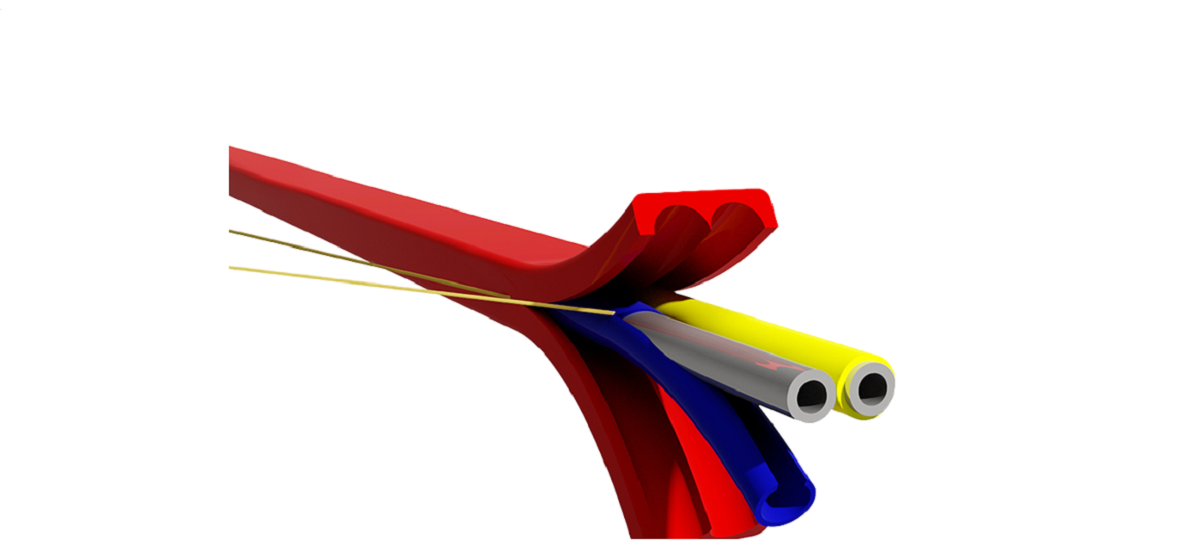

Prysmian Downhole Technology recognised this weakness and responded by developing Safety-Strip®. By adding a continuous tear cord into downhole cable, capillary tube or flatpack encapsulation, it makes it easier, faster and a lot safer to remove the outer jacket.

Safety-Strip® is now used by operators and oilfield service companies around the world in intelligent well systems, chemical injection applications and with pressure or temperature gauges and safety valves.

Safety-Strip® is available in a wide range of configurations, materials and dimensions to meet the demands of the most commonly faced downhole applications. Safety-Strip®, is a registered trademark and is patented in Canada, Europe, and the US with a patent is pending in Brazil.

Benefits

Safety-Strip® eliminates the need for open blade so reduces the risk of injury and lost time.

Safety-Strip® eliminates the risk of damage to the enclosed cable so improves system reliability.

Safety-Strip® is easy and fast to use, requires no special tools or particular expertise and significantly reduces rig time.

Control Lines & Flatpacks

-

Control Lines: Cables for harsh environment applications such as chemical injection or well monitoring

-

Flatpacks: Single and dual pass encapsulation featuring Prysmian Safety-Strip® technology

Business Stories

GALLERY

BROADBAND

Power Grids

Telecoms

POWER GRIDS

POWER GRIDS

Telecoms

Power Grids

Industries

BUSINESS

Telecoms

Transportation & Mobility

Power Grids

Telecoms