-

Weatherproof line wire consists of single conductor covered with either Linear Low-Density Polyethylene (LLDPE) or Cross-linked Polyethylene (XLPE). Conductors may be compact or concentric strand of ACSR, A1 or A2 or solid, compact or concentric strand copper. Weatherproof line wire meets the requirements of CSA C68.9 and the ANSI/ICEA S-70-547 specification, as applicable.

-

Triplex NS75/NS90 Service Drop Cable is intended to deliver single phase power from the secondary overhead power line or polemounted transformer to the service entrance conductors at the user’s building or other structure. NS75/NS90 cable may also be used as pole line secondary with service splices at the pole (also refer to CEC rule 12-318). NS75/NS90 cable is rated for use on systems having nominal voltages of 600 V or less.

-

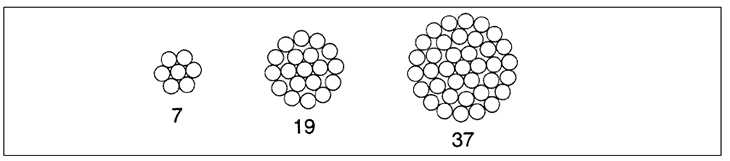

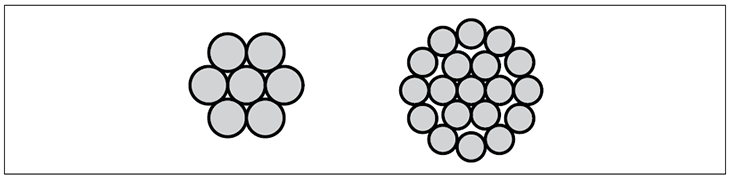

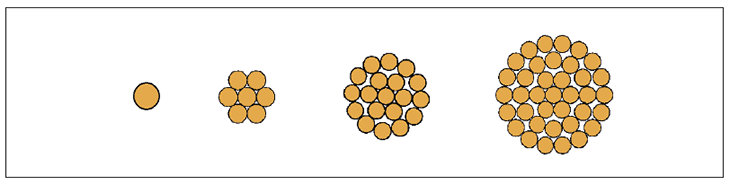

A2 conductors are high strength aluminum alloy, concentric-lay-stranded conductors. They are similar in construction and appearance to the A1 or AAC all-aluminum conductors. The conductors are manufactured in accordance with the requirements of the latest applicable issue of CAN/CSA C61089. A2 or AASC (Aluminum Alloy Stranded Conductor) are CSA reference terms. The A2/AASC conductors are manufactured from a heat-treated, magnesium-silicon high strength aluminum alloy. The aluminum strands consist of a concentric stranded cable of 7, 19, 37, or more wires. The sizes and strandings listed on the following pages are common examples used in overhead lines.

-

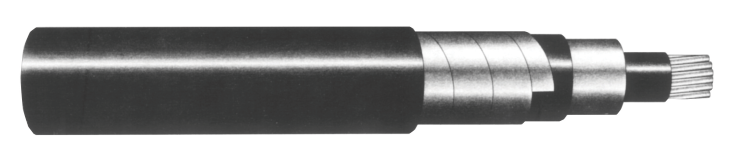

Cross-linked semi-conducting conductor shield, insulation and semi-conducting insulation shield are extruded over a solid or stranded aluminum or copper conductor and cured in a single operation. An uncoated copper tape (helically applied), polyester separator tape and extruded black PVC jacket are applied over the cable core.

-

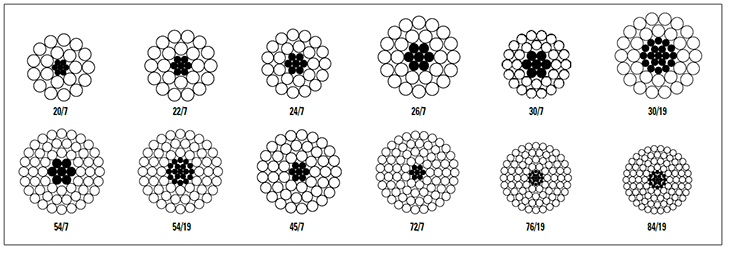

ACSS is a composite concentric-lay-stranded cable. ACSS conductors are manufactured in accordance with the latest issue of ASTM B856. The steel strands form the central core of the cable, around which is stranded one or more layers of aluminum 1350-O wires. The “O” temper of the aluminum, a fully annealed or soft temper, causes most or all of the mechanical load on ACSS to be carried by the steel. Standard ACSS designs are manufactured with regular-strength Class A zinc- 5% aluminum mischmetal alloy-coated steel core (/MA2). The steel core may consist of 7, 19, 37 or more wires.

-

Single conductor cable with stranded or solid aluminum or copper conductors, triple extruded insulation system consisting of a thermosetting semiconducting conductor shield, high dielectric strength VOLTALENE® TRXLPE insulation, thermosetting semiconducting insulation shield, LC Shield®, linear low-density polyethylene (LLDPE) jacket.

-

Bare soft copper grounding conductors are solid or concentric-lay-stranded, consisting of one or more layers of wire wrapped helically around a straight round central wire. Each successive layer has six wires more than the layer immediately beneath. Greater flexibility is afforded by using Class B stranding. The direction of lay for the outer layer is left-hand lay. In multilayer constructions, the direction of lay for each successive layer is reversed. Copper ground wires are manufactured using annealed soft copper wire and are manufactured in accordance with the requirements of the latest applicable issues of the ASTM specifications B3 and B8.

North America

Choose Country

- Europe

-

America

America

- LATAM

-

Asia Pacific

Asia Pacific

-

Africa

Africa

close

Missing block: prysmian_extra_service_menu