AIRGUARD® XP Fiber Optic Cable (Canada)

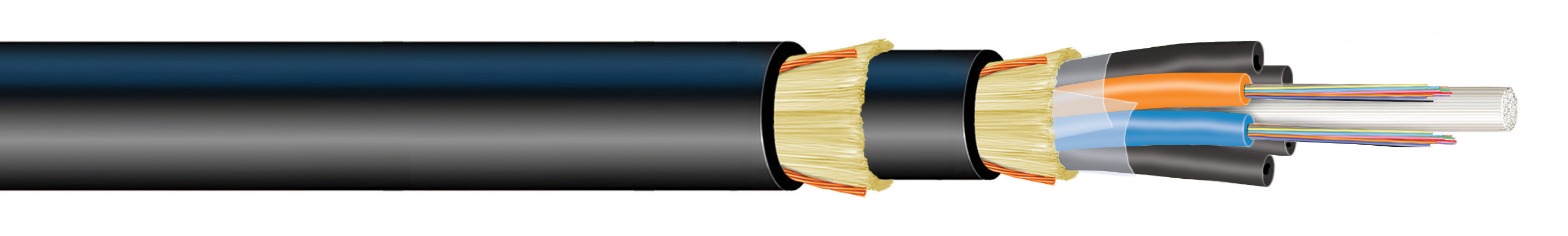

AIRGUARD® XP combines world-class mechanical protection, chemical protection, and user friendliness into a family of robust industrial optical fiber cables. AIRGUARD® XP joins Prysmian’s existing brands of AIRGUARD® low voltage and medium voltage cables.

In industrial, harsh environments, the presence of aggressive chemicals such as hydrocarbons, solvents, acids, and bases can damage traditional fiber cables. AIRGUARD® XP resists those harsh elements. In fact, the AIRGUARD® XP family surpasses the rigorous UL 2556 requirements for Oil & Gasoline Resistance.

AIRGUARD® XP goes head-to-head with interlocking armor cables in the areas of impact and crush resistance. Because interlock armor contains metallic armoring, it is stiff and heavy and requires grounding. A severe impact or crush may cause permanent deformation to the metallic armor. The AIRGUARD® XP, all-dielectric version, overcomes these drawbacks and can be installed in trays/ladders alongside copper communications or power-conducting cables, providing greater flexibility & user friendliness.

AIRGUARD® XP cables meet or exceed key industry standards such as ANSI/ICEA 696, CSA 22.2, UL 1277, and Telcordia GR20. The robust all-dielectric double jacket carries listings for sunlight resistance (SUN RES) and direct burial (DIR BUR). This cable is extremely versatile and can be used in low-temperature applications down to -50°C (-58°F) and in properly engineered, self-supporting aerial applications.

The dual jacket, single corrugated steel tape option is also SUN RES and DIR BUR listed and provides optimal rodent protection in direct buried applications.

Resources

- Fiber Specialty Ordering Guide

- Color Code Guide for Fiber Optic Specifications

- Fiber Code Addendum

- International Standards and Fiber Products Table

Part Numbers

XPRLTM-12-B1-006-E3, XPRLTM-12-B1-012-E3, XPRLTM-12-B1-024-E3, XPRLTM-12-B1-036-E3, XPRLTM-12-B1-048-E3, XPRLTM-12-B1-072-E3, XPRLTM-12-B1-096-E3, XPRLTM-12-B1-120-E3, XPRLTM-12-B1-144-E3, XTRLTM-12-B1-216-E3, XPRLTM-12-B1-288-E3, XPRLTMD-12-B1-006-E3, XPRLTMD-12-B1-012-E3, XPRLTMD-12-B1-024-E3, XPRLTMD-12-B1-036-E3, XPRLTMD-12-B1-048-E3, XPRLTMD-12-B1-072-E3, XPRLTMD-12-B1-096-E3, XPRLTMD-12-B1-120-E3, XPRLTMD-12-B1-144-E3, XTRLTMD-12-B1-216-E3, XPRLTMD-12-B1-288-E3

Features and Benefits

- Suitable for tray installations

- Hydrocarbon (kerosene, gasoline, lubricating oil) resistant

- Resists chemical degradation in industrial environments

- Resistant to jet fuel & de-icing chemicals for airport applications

- Flame-retardant, black UV-resistant outer jacket

- Smaller & lighter than comparable metallic armored designs

- Available with bend-insensitive single-mode & multimode fibers

- Proven stranded loose tube cable design for long-term reliability

Specifications and Ratings

Applications: AIRGUARD® XP cables are extremely rugged, indoor/outdoor loose tube cables providing unsurpassed performance in the most challenging applications where extreme exposures to chemicals, oils, temperature, or compressive and tensile loads are present

Flame Ratings

- XPRLTM = OFNG- LS/FT4 ST1 flame and low smoke rating

- XPRLTMD = OFCG-LS FT4 ST1 flame and low smoke rating

Fiber Count: 2 to 288

Fiber Types

- Single-mode (SMF, bend-insensitive)

- Multimode (62.5/125-OM1, 50/125-OM2, OM3 & OM4)

Standards: ANSI/ICEA S-104-696, CSA C22.2 No 230/232, UL-1277, UL-2556 4.2.8.3 “Oil Resistance” PR11, UL-2556 4.2.8.4 “Gasoline Resistance” GR11, UL 1277 & CSA 22.2 230 Direct Buried Rated: DIR BUR, UL 1651 & CSA 22.2 230 UV Resistance Rated: SUN RES, Telcordia GR-20, CE RoHS Compliant

Registered Supplier: TL 9000, ISO 9001, ISO 14001, and OHSAS 18001