CVTC® Cable - SPEC 2350

Product description

Part Numbers

366160, 337270, 337360, 337280, 337290, 337300, 337310, 337320, 337330, 337340, 337350, 319810, 319870, 337370, 3382260, 337390, 337400, 337410, 337420, 337430, 337440, 337450

Conductor

- 18 AWG and 16 AWG bare, annealed copper per ASTM B3

- Class B stranding per ASTM B8

Insulation

- Flame-retardant Cross-linked Polyethylene (XLPE)

- Color-coded per ICEA Method 1: Pairs - black and white; Triads - black, white and red. One conductor in each pair or triad is printed alpha-numerically for easy identification

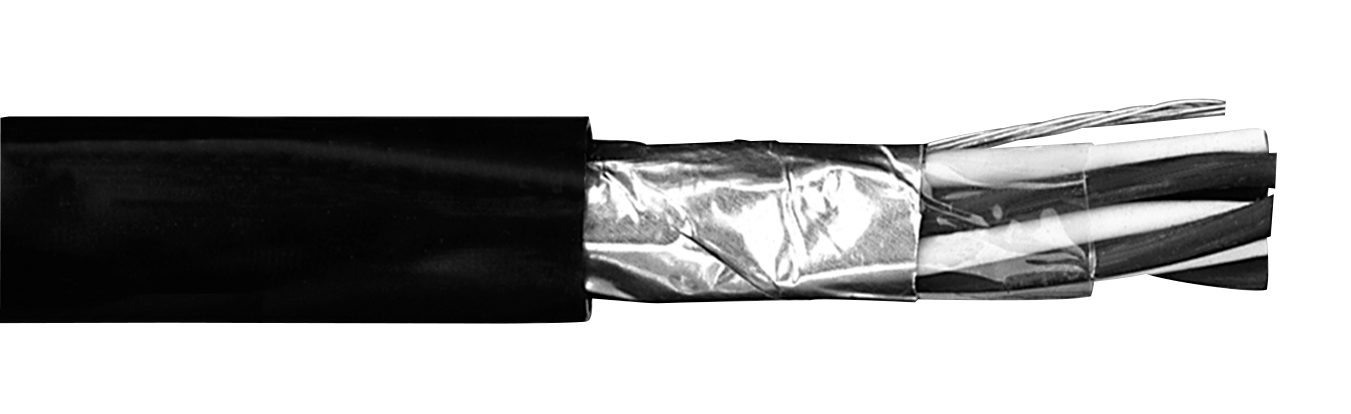

Shield

- Overall shielded pairs/triads

- Overall shield is Flexfoil® aluminum/polymer in contact with stranded tinned copper drain wire

Jacket

- Lead-free, flame-retardant, sunlight-resistant Polyvinyl Chloride (PVC)

Applications

- In free air, cable tray, raceways or direct burial

- In wet or dry locations

- Permitted for use in Class I, Division 2 industrial hazardous locations per NEC

- Permitted for Exposed Run (ER) use in accordance with NEC for 3 or more conductors

Features

- Rated at 90˚C wet or dry

- Ripcord applied to all cables with jacket of 60 mils or less

- Meets cold bend test at -25˚C

- Type ER versions meets crush and impact requirements of Type MC cables.

- Sunlight- and weather-resistant

- Excellent flame resistance

- Excellent physical, thermal and electrical properties

- Excellent moisture resistance

- Good resistance to abrasion and heat deformation

- Provides good oil and chemical resistance

Compliances

- Industry Compliances:

- UL 1277 Type TC, UL File # E57179

- UL 1581

- ICEA S-73-532/NEMA WC57

- RoHS Compliant

- Flame Test Compliances:

- UL 1581/UL 2556 VW-1

- UL 1685 Vertical Flame Test

- IEEE 383

- IEEE 1202

- CSA FT4

- Other Compliances:

- EPA 40 CFR, Part 261 for leachable lead content per TCLP

- OSHA Acceptable

Packaging

- Material cut to length and shipped on non-returnable wood reels