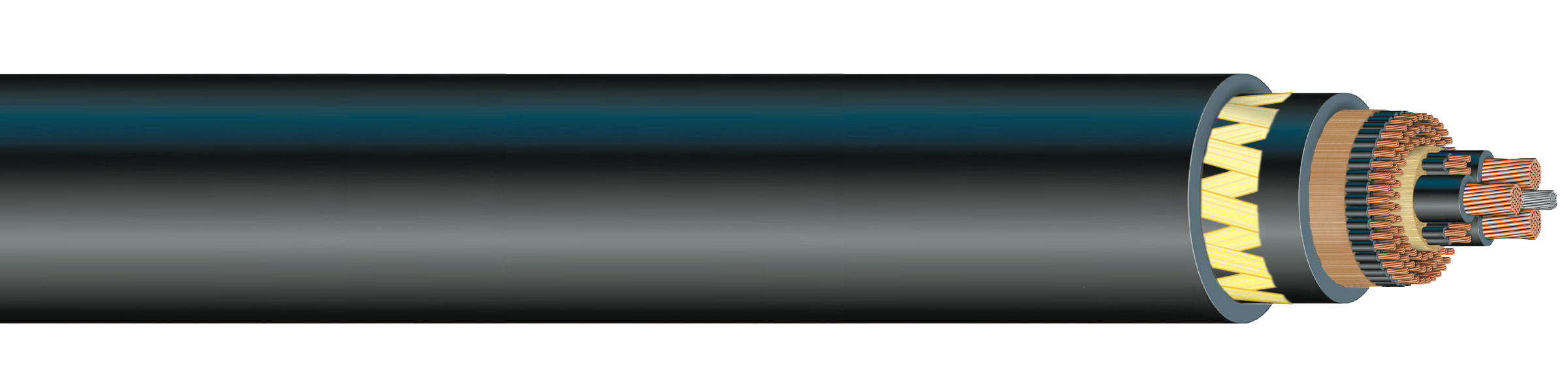

Bridge Traveling Cable

These cables are multi-conductor types rated for 600 and 2000 volts, specifically designed for applications that involve flexing, such as on bascule, lift, and swing bridges. They meet a specific combination of power, control, and signal circuit requirements, including fiber-optic components, and can contain up to 125 conductors with a diameter of up to 5 inches (12.7 cm). Additionally, an empty conduit can be integrated into the cable design.

These cables have been developed through a long-standing relationship with a diverse range of end users and specifiers, including local Departments of Transportation (DOTs), architects, engineers, and contractors. They are engineered to perform reliably even under the harshest conditions. The features listed below are standard, but modifications can be made upon request. All cables are tailored to meet specific application requirements.

Specifications and Ratings

- ICEA S-73-532, NEMA WC-57

- ICEA S-95-658, NEMA WC-70

Design Parameters

Central Strength Member: Flexible, preformed Type 302 or 304 stainless steel aircraft cable.

Conductor: Annealed uncoated copper in accordance with ASTM B-174 for 10 AWG and smaller or ASTM B-172 for 9 AWG or larger, class K stranding, and section 2 of ICEA S-95-658. Optical fibers are also available.

Insulation: Ethylene propylene rubber (EPR) meeting the Type II requirements of ICEA S-73-532, NEMA WC 57 Table 3-2 (22 to 16 AWG), 600 volt or ICEA S-95-658, NEMA WC70, Table 3-1 (14 AWG or larger, 600 to 2000 volt).

Circuit Identification: Surface printed legend with number/color: (1-BLACK, 2-WHITE, 3-RED, etc.) per ICEA S-73-532, NEMA WC 57-1990, Method 3 and Table E-1.

Assembly: Cable components are assembled with non-hygroscopic fillers, as required by the application. The cabled core is wrapped with a moisture-resistant binder tape. Maximum lay length shall be 12x O.D.

Inner Jacket: Arctic, heavy-duty and UV-resistant Neoprene® polychloroprene rubber per ICEA S-95-658, NEMA WC-70.

Cable Jacket Reinforcement: Two layers of Kevlar® aramid fibers are applied helically in reverse directions between the two jackets.

Outer Jacket: Arctic, heavy-duty and UV-resistant Neoprene® polychloroprene rubber per ICEA S-95-658, NEMA WC-70. The total jacket thickness is shown in the datasheet table.

Identification: The outer jacket can be marked with identifying information, including construction, contract, manufacturing date/location, and sequential length.