MOR® Polyrad® Type P Control Cable (10, 12 & 14 AWG)

Part Numbers

326120, 279320, 279310, 281180, 302600, 281170, 356760, 279170, 352480, 315770, 356770, 279180, 315820, 356780, 279190, 356790, 356800, 356810, 281160, 279200, 279210, 356820, 356830, 355760, 356840, 287710, 356850, 281210, 356860, 356870, 287730, 356880, 356890, 356900, 326130, 279220, 49 279230, 356910, 316620, 356930, 34 35694, 356950

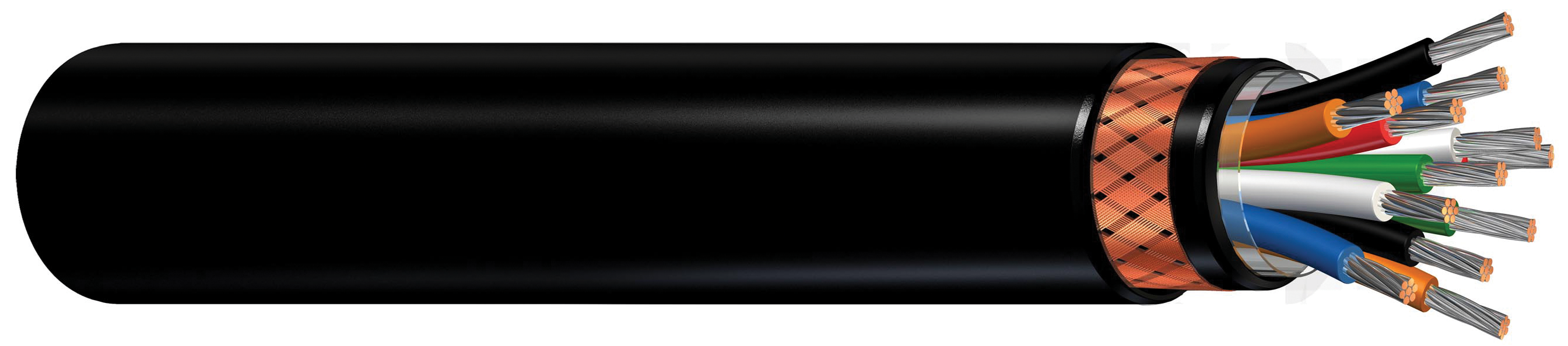

Product Construction

Conductor: 14 AWG thru 10 AWG soft annealed tinned copper flexible strand

Insulation

- Polyrad® XT-125 Irradiated Cross-linked Polyolefin (XLPO)

- Color Code: Per IEEE 1580 Table 22

Cable Core

- Cabled with fillers when required

- Core binder tape when required

Jacket: Black Irradiated Cross-linked Chlorinated Polyethylene (XL-CPE)

Armor: Bronze braid 88% minimum coverage

Sheath: Mud Oil-Resistant, Black Irradiated Cross-linked Chlorinated Polyethylene (XL-CPE)

Print: MOR® POLYRAD® XT-125 (UL) E85994 BR782B 110C XX/C XXAWG -- (CSA) LL 9755 SPEC 245/1309 FT4 -40C SR 600/1000 V -- IEC 1 KV 60332.3A IEEE 1580 TYPE P (ETL) 109229 YEAR OF MFG SEQUENTIAL FOOTAGE MARK

Applications

- Offshore oil and gas drilling platforms, MODUs, ships and FPSOs

- Land-based oil and gas drilling rigs

- Suitable for use in Class I, Division 1 and Zone 1 Hazardous Locations when installed in accordance with API-RP14F

Features

- Meets NEK 606 mud oil resistance requirements with ester-based muds

- Meets UL 2225 crush and impact requirements of Type MC-HL cables

- Flexible stranding to facilitate ease of cable installation and termination

- Temperature rated at 125°C for long life, higher ampacities and protection from thermal overloads

- Meets cold bend test at -55°C

- Meets cold impact test at -40°C

Compliances

Industry: API-RP14F, CSA C22.2 No. 245 Type X110, IEEE 1580-2010 Type P, IEC 60092-350, Mud oil-resistant, UL 1309 Type X110, UL Listed 110°C Marine Shipboard Cable

Flame Test: IEEE 1202, IEC 60332-3-22 Cat. A (supersedes IEC 60332-3A), CSA C22.2 No. 0.3 FT4