Environmental Performance

Reducing energy consumption

Toggle DetailsGreenhouse gas emissions

Toggle DetailsFurthermore, since 2011 we participate in the CDP (ex Carbon Disclosure Project), an international initiative aiming to help meet the Kyoto Protocol's targets for worldwide reduction in greenhouse gases.

Reducing water consumption

Toggle DetailsReducing hazardous and non-hazardous waste

Toggle DetailsRecycling waste

Toggle DetailsBABAA-Compliant Optical Fiber Cables

Prysmian optical fiber cores are manufactured in our Claremont, North Carolina Optical Fiber and Cabling plant. We apply the cladding in the same plant, and all of our preform glass is of U.S. origin.

And we're continuing to expand our overclad facilities in the United States, creating new manufacturing jobs along the way.

Learn more about our BABAA-compliant solutions below:

SiroccoHD™ Cables

Toggle Details

Leverages the capabilities of our industry-leading, 200 μm Bend-Insensitive Fiber to provide some of the highest fiber densities available. Prysmian offers solutions for microducts ranging from 8 mm to 14 mm, or larger, inside diameters. These small diameter cables combine high reliability with reduced size and weight for optimum blowing performance.

ezSPAN® ADSS All-Dielectric Self-Supporting Loose Tube

Toggle Details

Provides reliable self-support performance for up to 1200 feet (365 meters). These cables uniquely combine flexible buffer tubes and swellable water-blocking to make ezSPAN the easiest ADSS cables to prep and access.

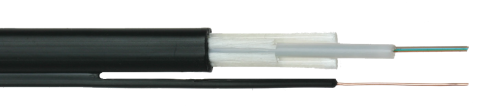

ResiLink™ ADF Flat Drop Dielectric Cable (1 to 24 Fibers)

Toggle Details

All-dielectric flat drop cable (1 to 24 Fibers) for self-support, duct, or buried applications

ResiLink™ TF Flat Drop Toneable Cable (1 to 24 Fibers)

Toggle Details

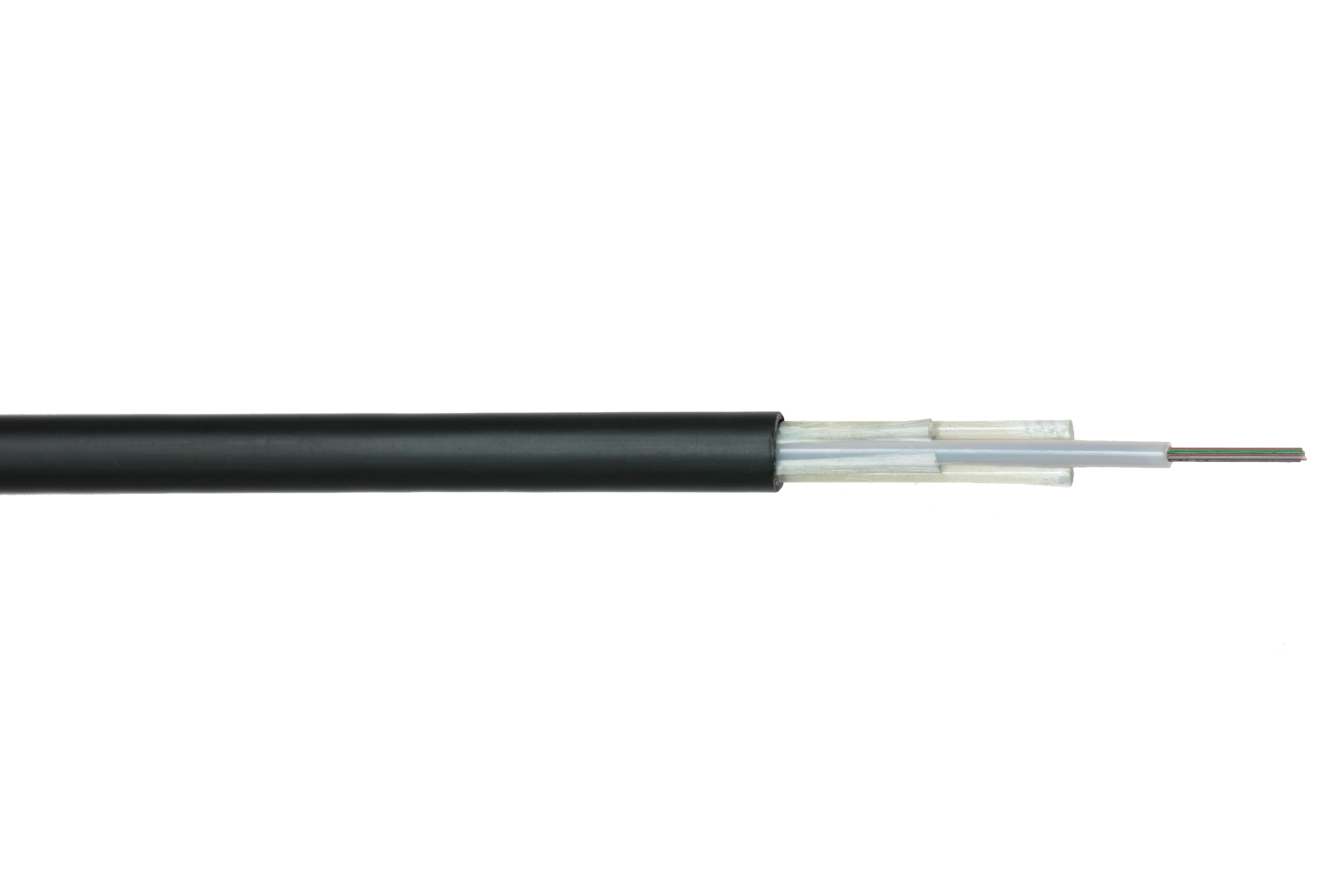

ExpressLT™ Dry Loose Tube Cable (2.5 mm)

Toggle Details

A versatile, multi-purpose dry loose tube cable family designed for ease of use and buffer tube mid-span storage applications.

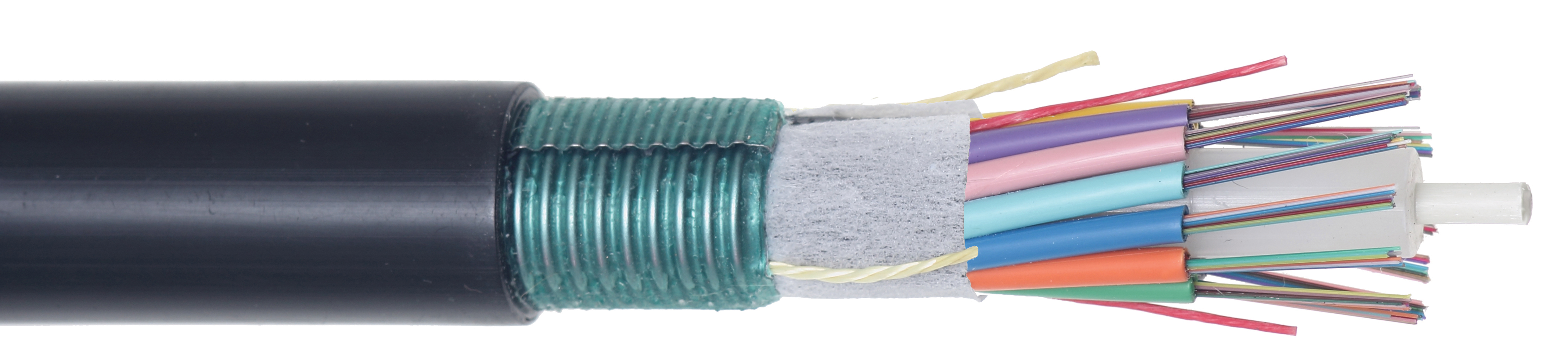

ExpressLT™ All-Dielectric Armor Cable

Toggle Details

A dual jacket design with multiple layers of fiberglass provides dielectric armoring, superior tensile strength, and small rodent retardant protection.