What You Need to Know About Composite Access Control Cables

By Travis Starnes, Product Manager, Industrial & Construction, Prysmian North America

Security infrastructure has evolved significantly beyond simple locks and keys. Modern access control systems now integrate card readers, biometric scanners, electronic locks, and monitoring equipment into sophisticated networks that protect commercial buildings, educational institutions, and government facilities. At the heart of these systems lies specialized cabling that must reliably transmit power and data between multiple components. Composite access control cables have become the backbone of contemporary security installations, combining multiple conductors and cable types within a single jacket to streamline installation and improve system performance. Cable distributors who stock these specialized products position themselves to serve the growing demand for integrated security solutions across commercial construction and infrastructure projects.

Access Control Cabling for Modern Security

The shift toward electronic access control has transformed how buildings manage entry points and secure sensitive areas. Today's facilities employ networked systems that authenticate credentials, log entry attempts, and integrate with broader security platforms. These systems demand a reliable cabling infrastructure capable of powering door locks, transmitting card reader data, connecting door position sensors, and linking request-to-exit devices.

Traditional installation methods often involved running separate cables for each function, creating complex cable bundles that consumed valuable conduit space and increased labor costs. Installers faced the challenge of pulling multiple individual cables through tight pathways, maintaining proper separation between power and data lines, and managing dozens of termination points at each door. The complexity multiplied across facilities with hundreds of controlled access points, turning cable management into a significant project consideration.

Composite access control cables address these challenges by consolidating multiple cable functions into a single jacket. Rather than pulling four separate cables to each door, installers can now run a single composite cable containing all necessary conductors. This approach reduces installation time, minimizes potential connection errors, and creates cleaner, more organized cable pathways throughout the facility.

What Is a Composite Access Control Cable?

A composite access control cable combines multiple conductor groups within a single outer jacket, with each group designated for specific security system functions. The typical configuration includes four distinct elements that correspond to standard access control components found at most secured entry points.

The first element usually consists of four 18 AWG conductors for powering electronic door locks. These heavier-gauge conductors handle the current requirements of fail-safe and fail-secure locking mechanisms while maintaining minimal voltage drop over extended cable runs. The second element incorporates three twisted pairs of 22 AWG conductors for card reader communications, supporting various reader technologies from proximity cards to biometric scanners.

The third element provides two 22 AWG conductors for door contact monitoring, enabling the system to detect whether doors remain properly closed and secured. The fourth element adds another set of four 22 AWG conductors for request-to-exit devices and auxiliary functions, accommodating motion sensors, push buttons, and other egress components.

Each element within the composite cable features color-coded jackets that simplify field identification and termination. Gray jackets typically indicate lock power conductors, orange marks card reader pairs, white identifies door contact wiring, and blue designates request-to-exit connections. The standardized color scheme helps installers quickly identify the correct conductors during installation and troubleshooting.

Benefits of Composite Access Control Cables

1. Simplified Installation Process

Composite cables dramatically reduce installation complexity by eliminating the need to pull multiple individual cables through conduits and raceways. Installers save significant time during the rough-in phase by handling only one cable per door rather than four separate runs. The single-pull approach also reduces the risk of damaging cables during installation, particularly when navigating tight bends or crowded pathways.

2. Reduced Labor Costs

Labor is one of the largest expenses in security system installations. By reducing cable-pulling time, composite cables enable contractors to complete projects faster and move crews to the next job sooner. The simplified termination process, aided by clear color coding and organized conductor groups, further reduces the hours required for system commissioning.

3. Space Efficiency in Conduits

Building codes often limit conduit fill ratios, restricting the number of cables that can occupy a given pathway. Composite cables maximize available space by combining multiple functions within a single jacket diameter. This efficiency becomes particularly valuable in renovation projects where existing conduits must accommodate new security infrastructure alongside legacy systems.

4. Enhanced System Organization

The integrated design of composite cables creates inherently organized cable runs, simplifying long-term maintenance and system modifications. Technicians can quickly trace cables from control panels to door locations without having to sort through tangles of individual wires. The standardized color coding and element identification reduce troubleshooting time when diagnosing system issues.

5. Consistent Performance Standards

Manufacturing composite cables to unified specifications ensures consistent electrical characteristics across all conductors. Prysmian's composite access control cables meet the requirements of NEC Article 800 and carry the appropriate fire ratings for both riser (CMR) and plenum (CMP) installations. Our controlled manufacturing environment produces cables with uniform impedance, capacitance, and attenuation characteristics, ensuring reliable system operation.

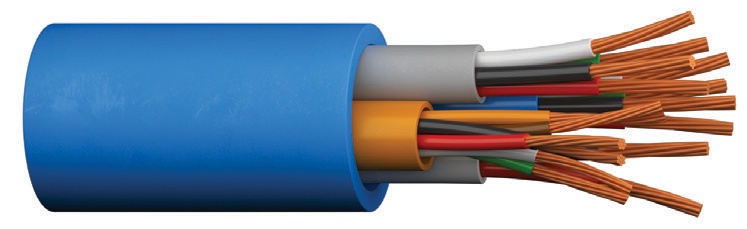

CMR Cable

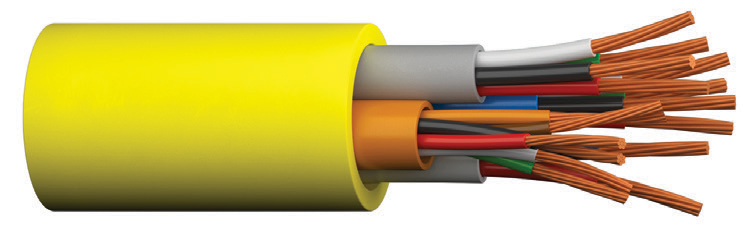

CMP Cable

Where Composite Cables Are Used

Commercial office buildings are among the largest markets for composite access control cables, with installations ranging from small professional suites to massive corporate campuses. These facilities typically feature dozens or hundreds of controlled access points, including main entrances, elevator lobbies, server rooms, and executive areas. The scalability of composite cable systems accommodates both initial construction and future expansion as security needs evolve.

Educational institutions, from elementary schools to universities, rely on access control systems to protect students, staff, and assets. Composite cables support the complex security requirements of academic environments, including classroom lockdown capabilities, after-hours access restrictions, and integration with campus-wide emergency notification systems.

Healthcare facilities present unique security challenges that composite cables help address efficiently. Hospitals must balance public accessibility with restricted areas for pharmaceuticals, patient records, and sensitive equipment. The consolidated cabling approach simplifies installations in environments where infection control and minimal disruption to operations remain paramount concerns.

Government buildings and military installations implement stringent access control measures that often exceed commercial standards. Composite cables support high-security applications, including multi-factor authentication systems, mantrap configurations, and integration with intrusion detection networks. The shielded versions of these cables provide additional protection against electromagnetic interference and signal interception.

Data centers and technology facilities protect critical infrastructure with sophisticated access control systems that monitor and log every entry attempt. Composite cables connect biometric readers, badge scanners, and video verification systems while maintaining the cable organization essential for these precision environments.

Composite vs. Traditional Access Control Cables

The advantages of composite cables are clear when comparing installation requirements against traditional discrete wiring methods. Running individual cables for each access control function typically demands four separate pulls per door, quadrupling the installation time and labor costs. Discrete cables also consume more conduit space, potentially requiring larger raceways or additional pathways to accommodate all necessary wiring.

Traditional installations often result in cable congestion at connection points, making it difficult to identify specific conductors during termination or troubleshooting. The absence of standardized color coding across different cable manufacturers can lead to wiring errors that compromise system functionality. Discrete cables may also suffer from inconsistent quality when sourced from multiple suppliers, introducing variables that affect system performance.

Composite cables provide superior value despite potentially higher per-foot material costs compared to individual cables. The labor savings achieved through simplified installation typically offset any premium pricing within the first few doors of a project. The long-term benefits of improved organization, easier maintenance, and reduced troubleshooting time further justify the investment in composite cable solutions.

Stocking and Supply Considerations for Distributors

Successful distribution of composite access control cables starts with understanding regional market demands and construction patterns. Urban markets with substantial commercial development typically consume larger quantities of plenum-rated cables for high-rise installations. Suburban and industrial areas may favor riser-rated products for low-rise buildings and warehouse facilities.

Inventory management should account for both standard configurations and specialized variants. While four-element composite cables serve most applications, some projects specify cables with all shielded elements for enhanced electromagnetic protection. Others may need partially shielded configurations that balance performance with cost considerations. Maintaining appropriate stock levels of both variations ensures distributors can fulfill orders promptly without carrying excessive inventory.

Lead time planning becomes crucial for large project support. Major construction projects often require thousands of feet of composite cable delivered in stages aligned with construction schedules. Establishing relationships with manufacturers like Prysmian ensures reliable supply chains and access to technical support during project specification and implementation phases. Price positioning should reflect the total value proposition rather than simple per-foot comparisons. Educating customers about labor savings, reduced conduit requirements, and long-term maintenance benefits helps justify premium pricing over discrete cable alternatives. Providing installation time calculators and cost comparison tools can demonstrate the economic advantages of composite solutions.

Technical support capabilities distinguish leading distributors from commodity suppliers. Staff training on access control system design, code requirements, and installation best practices enables distributors to serve as consultative partners rather than simple order takers. This expertise becomes particularly valuable when customers face unique installation challenges or need guidance in selecting appropriate cable specifications.

Contact Prysmian for Access Control Cable Solutions

As the world leader in cable technology and innovation, Prysmian brings unmatched expertise to the access control market through North America's most comprehensive portfolio of construction and infrastructure cable solutions. Our composite access control cables, manufactured under the trusted CAROL® brand, deliver the quality and reliability that security professionals demand for critical installations. We offer both plenum and riser-rated configurations with multiple shielding options to meet diverse project requirements. Our technical team provides specification assistance, installation guidance, and ongoing support to ensure successful project outcomes. Whether you're stocking for regular customer needs or preparing for major project requirements, we maintain the production capacity and distribution network to meet your delivery expectations. Contact our team of cable industry experts to learn how Prysmian's composite access control cables can strengthen your position in the security market while providing the quality products your customers deserve.