-

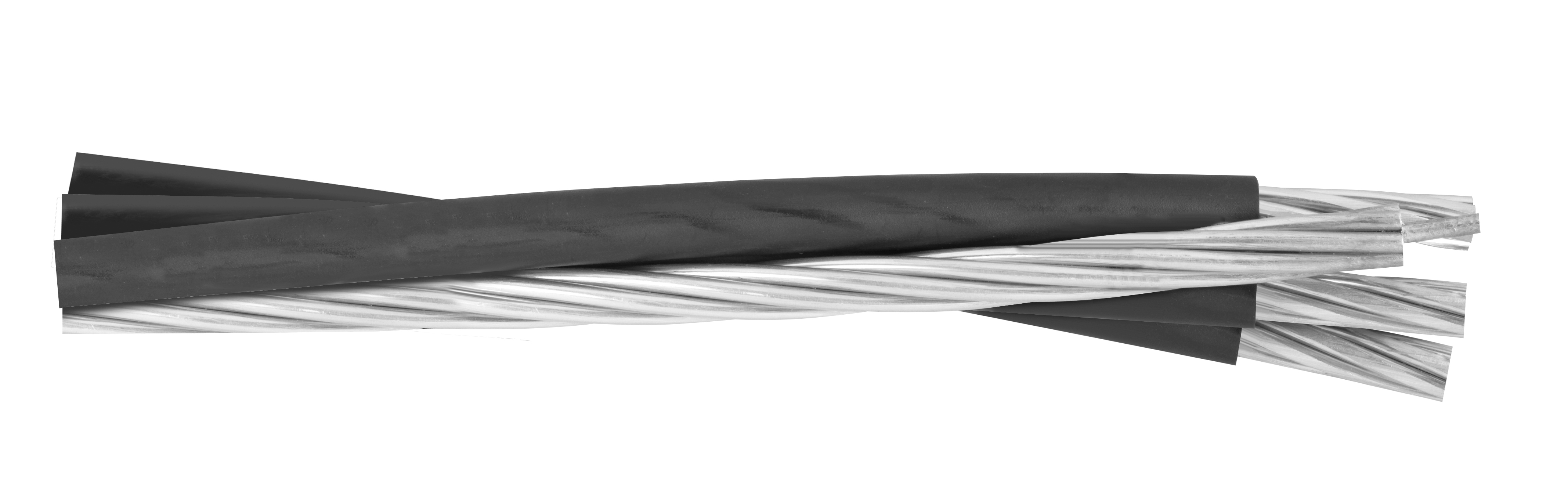

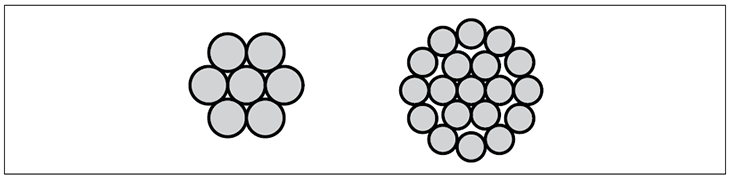

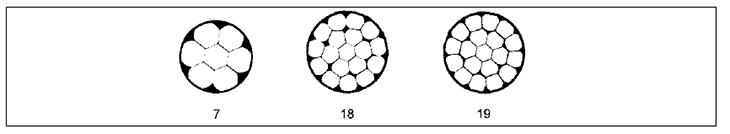

Cross-linked semi conducting conductor shield, insulation and semi-conducting insulation shield are extruded over a solid or stranded aluminum or copper conductor and cured in a single operation. Uncoated copper neutral wires (helically applied) and extruded-to-fill black jacket are applied over the cable core.

-

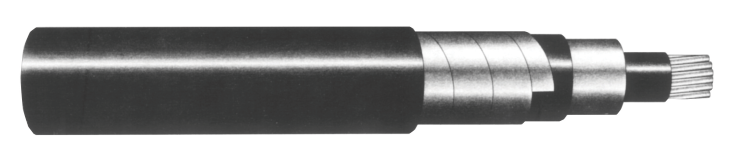

Cross-linked semi-conducting conductor shield, insulation and semi-conducting insulation shield are extruded over a solid or stranded aluminum or copper conductor and cured in a single operation. An uncoated copper tape (helically applied), polyester separator tape and extruded black PVC jacket are applied over the cable core.

North America

Choose Country

- Europe

-

America

America

- LATAM

-

Asia Pacific

Asia Pacific

-

Africa

Africa

close

Missing block: prysmian_extra_service_menu