Top 5 Cable Advancements Revolutionizing FTTH

By Matthew Brice, Senior Technical Marketing Manager, Digital Solutions, Prysmian North America

Exploring the Innovations Powering Next-Generation Fiber-to-the-Home Networks

Fiber-to-the-Home (FTTH) technology continues to connect communities with high-speed internet, supporting everything from smart homes to remote work and online entertainment. At the heart of this revolution are remarkable advancements in cable technology, which are making FTTH faster, more reliable, and easier to deploy than ever before. Here’s a look at the top five cable innovations transforming the FTTH landscape.

1. Bend-Insensitive Fiber (BIF)

Bend-insensitive fiber cables are designed to maintain optimal signal strength even when bent or twisted around corners or tight spaces. This innovation minimizes signal loss, reduces installation errors, and enables more flexible routing inside buildings and homes. BIF is a game-changer for dense urban environments and multi-dwelling units where space and cable routing options are limited.

Oftentimes, despite best intentions, networks become strained in the outside plant environment. BIF can protect against terminals that fall out of their mounting bracket, trees that rest on cables, and poor fiber management practices.

And some demanding applications in Multiple Dwelling Units (MDUs) require fiber that meets the most stringent bend requirements around baseboard corners, or that is stuffed into miniature pathways and enclosures. This wouldn’t be possible without BIF.

Prysmian’s BendBright™ fibers have been first to market for several iterations of ITU G.657.x standards, setting the benchmark for performance in these challenging situations. Since 2004, Prysmian has been first to market 5 times with innovations that help shape the future of FTTH and the density required to connect the backbone of these access networks to support the next generations of technology, including AI, VR, and IoT.

BendBrightXS and the full family of BB fibers not only have innovated on the performance of the glass, but the ColorLockXS™ technology allows for smaller coating diameters. Prysmian was the first to release a 180µm coated fiber in 2019, and we are proud to announce our BendBrightXS 160µm fibers in 2025.

2. Flat Drop Cables

Why are most drop cables in North America flat? They are very flexible and inflexible at the same time. Their flexibility comes from the different ways flat drop fiber-optic cables can be installed: aerial self-support, compact fit inside ducts, and direct burial. The unfortunate drawback to them is that the radial strength members do not allow 360 degrees of rotation like most round cables. For most, that tradeoff is more than acceptable because flat drop cables have the dominant market share.

So again, why are drop cables flat? It concerns the original Glass Supported Drop Wire used in telephone networks. Operators wanted to use the same (or similar) hardware and installation practices that they used with (fiber) glass-supported drop wire, also known as Aerial Service Wire (ASW).

If you notice, most wedge clamps today still reference 2-Pair and 6-Pair designs (aka B-Clamps and P-Clamps). Over the years, hardware suppliers have improved the designs to include longer bails and enhanced keeper plates that provide a stronger grip on the polyethylene jackets of flat fiber. Still, the body widths of the clamps mimic the original 2-Pair and 6-Pair designs. And while most flat drop cables fit a 2-Pair clamp, make sure you’re using the appropriate clamp for the type of fiber you’re using.

Choosing the proper clamp is more important now than ever as new flat cable designs enter the market. Due to the popularity of flat cables, higher fiber counts and longer spans are the trend. Longer spans will require more durable clamps than traditional telephone clamps. Prysmian has recently launched 3 new flat cables: ResiLink™ Mini-Flat, 36-48 Count ResiLink™ and EcoSpan™.

Prysmian’s Field Services Team is ready to help consult on the proper installation and management of these groundbreaking cables, ensuring high-quality, long-lasting access networks of the future.

3. Microduct and Microcable Technologies

Microducts and microcables are smaller, more flexible cables and conduits that facilitate easier, more efficient installation of fiber networks. These technologies enable providers to deploy fiber in existing ducts or crowded utility spaces with minimal disruption. Microcabling also supports incremental expansion, allowing operators to add capacity as demand grows without costly overhauls.

Air-blown fiber systems use compressed air to rapidly and precisely install fiber optic cables through microducts. This method reduces installation time, minimizes physical labor, and allows for flexible network scaling. It’s particularly valuable in areas where digging or traditional cable laying is impractical, expensive, or disruptive.

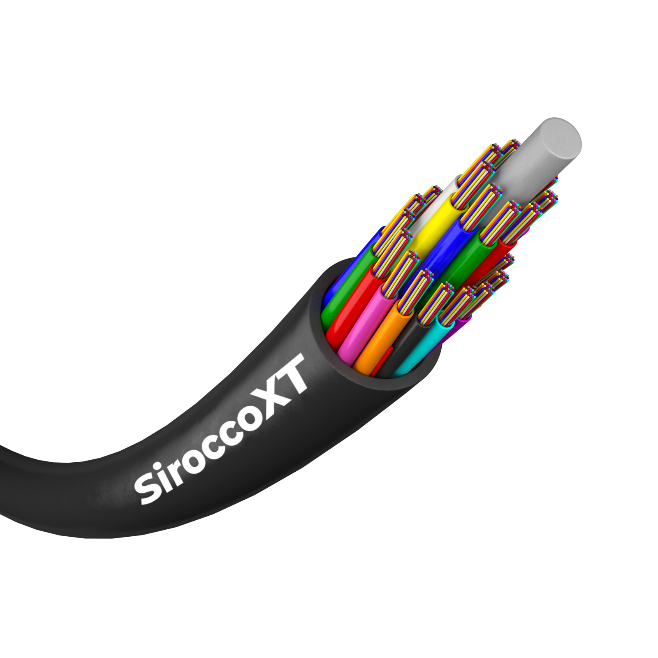

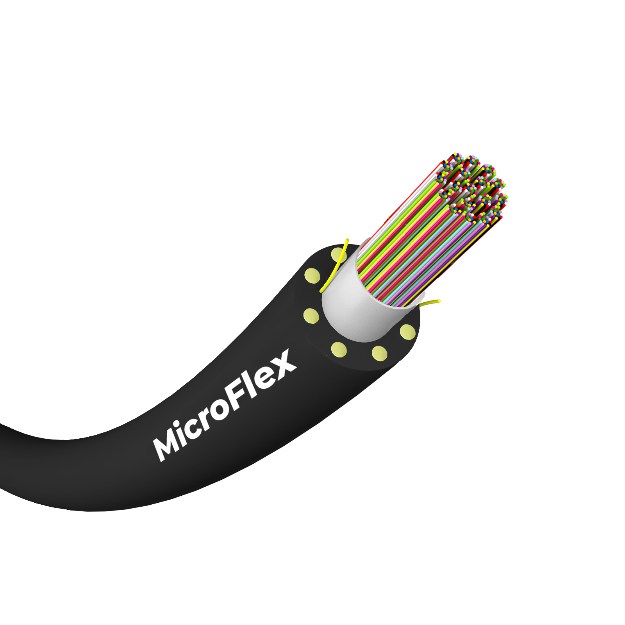

Prysmian’s Sirocco™ and MicroFlex™ families of micro cables have pushed the boundaries of cable densities, thanks to the BendBright fibers that contribute to ground-breaking cable sizes. In North America, particularly, micro cables were often only used in situations that required a specific diameter. FTTH overbuilds, particularly when overrides are required, require reduced diameters. Performing an override can save operators up to 80%, making it a very attractive solution.

Beyond situations that require smaller cables, operators now have greater flexibility to plan for future network use cases when fiber provisioning can be challenging. The ability to leverage a network for smart city, IoT, smart agriculture, cellular backhaul and other enterprise use cases can significantly extend the ROI of a given build.

4. Intermittently-Bonded Ribbon

Only Data Centers can truly sing the benefits of Intermittently-Bonded Ribbon cables today. What has that level of connectivity unlocked for access networks? As hyperscalers built the cloud, massive cables interconnected them to ensure high-bandwidth, high-capacity networks. This connectivity allowed your Google search results to run faster and your streaming video services to operate with less buffering and lower latency. So, while most likely an intermittently-bonded ribbon cable is not directly connecting customers at the edge of the network, it played a significant role in enabling the content utilized at home and commercially.

Prysmian’s FlexRibbon™ technology is our patented design and is used in more cable constructions than any other manufacturer offering this type of ribbon today. From our MassLink™ with FlexRibbon® tech cables, to our latest MicroFlex™ and EcoSpan™ designs, Prysmian is a leader in intermittently bonded ribbons for both indoor and outdoor applications.

5. Pre-Connectorized Solutions

You have three choices when you install fiber at the customer:

- Splice inside an enclosure

- Connect inside an enclosure

- Connect outside an enclosure

Pre-connectorized cables come with factory-terminated connectors, which significantly reduce installation time and the risk of field-termination errors. Installers can plug and play the cables into network hardware, streamlining the rollout of FTTH networks. This advancement is especially useful in large-scale deployments, helping providers accelerate service activation for new customers.

While splicing in a fiber network is inevitable, pre-connectorized solutions offer time and cost savings, especially as network density increases.

These cable innovations are key drivers in making FTTH more accessible, cost-effective, and robust. As the demand for high-speed internet continues to climb, ongoing advancements in cable technology will keep paving the way for a more connected future.

Prysmian’s ezDROP™ Preconnectorized Fiber Optic Drop Cable Assemblies offer a wide range of cable types that can be terminated to the industry standard HFOC hardened outdoor connector, or Optitap®. Prysmian also offers the ResiLink™ Mini-Flat with these assemblies, which further improve handling in the field by enabling quick connections for customers.

With Prysmian’s continued commitment to products that are Made Right Here, customers can rely on us to bridge the digital divide with innovative, affordable and BABA compliant cables and components.

Please note that OptiTap® is a registered trademark of Corning Incorporated.